Machining Education and Research Laboratory

LEPU History – The Laboratory for Education and Research in Machining was created in 1991 as a consequence of very important research in conventional machining operations developed at the School of Mechanical Engineering of the Federal University of Uberlandia - UFU

Most research projects at LEPU have participation and partnership established with metal-mechanic industries, mainly with tool manufacturers, casting, metallurgic, aerospace, and automotive industries. There is also the participation of specialists of other fields in engineering, which can enable transference of knowledge, therefore giving a multidisciplinary aspect, which is essential for a well succeed work.

The permanent staff of the LEPU is compound of four lecturers/researchers:

- Álisson Rocha Machado, PhD

- Arthur Alves Fiocchi, PhD

- Eder Silva Costa, PhD

- Leonardo Rosa Ribeiro da Silva, PhD

- Marcio Bacci da Silva, PhD

- Rosemar Batista da Silva, PhD

Other members of LEPU are: about 15 PhD students, 10 Master students and 20 under graduated students, Researcher beginners, and 4 technicians.

Objectives and competencies:

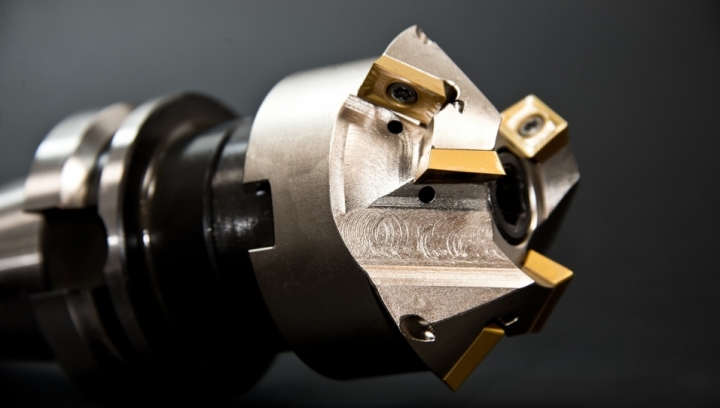

- Study on behavior of re-sharpened cutting tools – Partnership with OSG tool manufacturer, Embraer, and Fiat Powertrain Technology;

- Study on behavior of vegetable-based oils during turning and milling operations of medium carbon steels - Partnership with Gerdau S.A. and Castrol;

- Study on the contact of the workpiece (machined surface) with the flank face of the tool and determination of residual forces;

- Study on high coolant pressure supply when turning stainless steels;

- Operational aspects of CAD/CAM integrated system in machined surfaces;

- Evaluation of the performance of different grinding wheels on geometry quality of mold and die tools;

- Investigation of the influence of the application of comestible vegetable oils as cutting fluid in drilling and milling of SAE 1045 steel;

- Study of the influence of the material and geometry of tool-holders on the tool temperature in turning;

- Study in micro-machining operations;

- Use of laser texturing in coated cemented carbide tools

Some of recent research in development are:

- Characterization and determination of machinability index of aluminum alloys. Partnership with Mitsubishi, OSG Sulamericana de Ferramentas Ltda and CBA (Brazilian Aluminum Company);

-

- Study of the behavior of burr formation in end-milling of PH stainless steel grade, aiming its reduction and/or elimination. Partnership with Villares Metals

- Study of machinability of Ni-base superalloys - Inconel 751 e Inconel 718; and tool wear mechanisms developed when machining these materials. Partnership with Villares Metals

- Study of machinability of die and mold steels during the milling operation. Partnership with Villares Metals

- Investigation of machinability of various cast iron grades (grey cast iron, nodular cast iron, and austempered ductile iron) under high cutting speed. Partnership with Sandvik Coromant and Tupy S.A. Foundry Company.

- Grindability study of superalloys, cast irons and hardened steels.

- Application of solid lubricants dispersed in coolant in grinding with conventional abrasive wheels.

- Study of electromechanical impedance to monitor surface integrity of metal after grinding

- Influence of dressing parameters in grinding of Ti-6Al-4V alloy under different cutting variables

The Laboratory for Education and Research in Machining is available to host graduate and post-graduate students and researchers for short-term academic internship. The academic activities for this students are related research in machining process, that includes turning, milling, drilling, grinding, resharpening, lapping of metals and polimers.

Office hours: 07:30 a.m. to 11:30 a.m. and 1:30 p.m. to 5:30 p.m.

Coordinator: Arthur Alves Fiocchi

Technician in charge: Cláudio Gomes do Nascimento